How Adhesive Bead Width May Impact Your Bottom Line

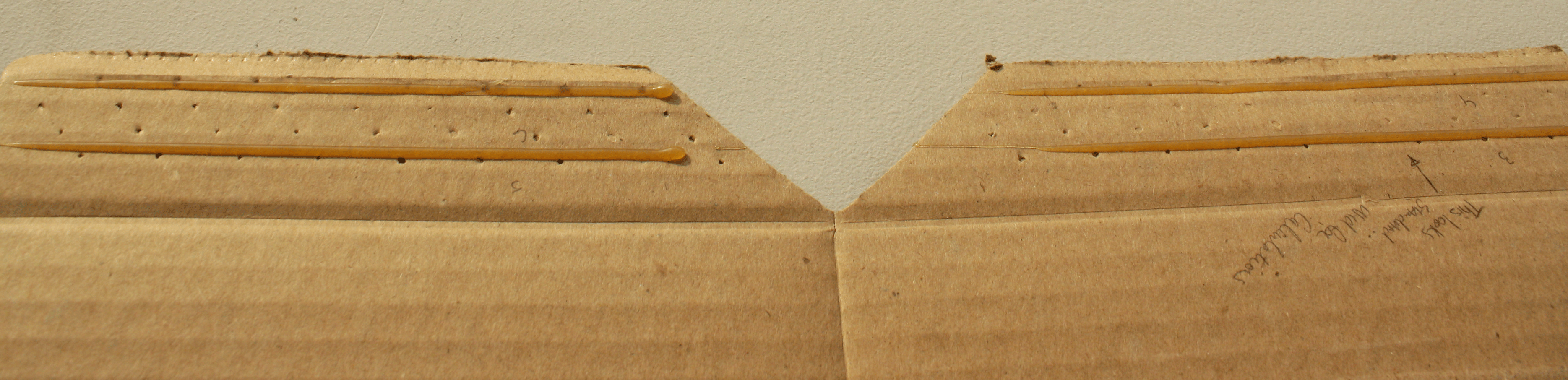

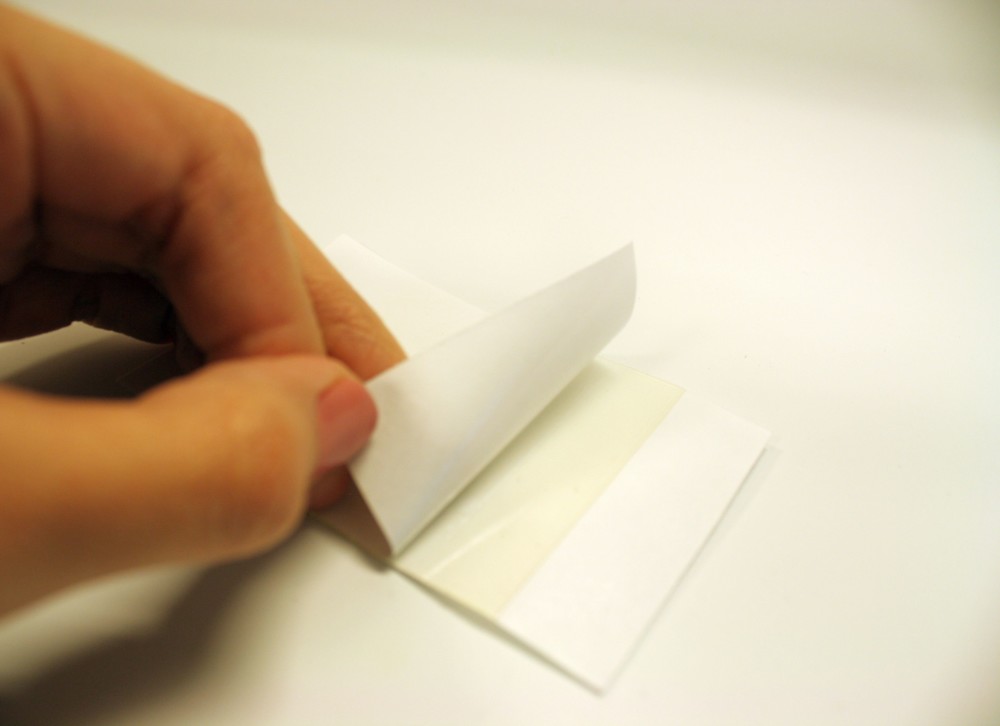

How much does the bead width of your adhesive matter? As it turns out, it matters quite a bit. Bead width is closely related to adhesive performance. Perhaps you begin seeing pop-opens or poor adhesion on your packaging line. While there are many possible causes for these issues, your adhesive bead width could be one of