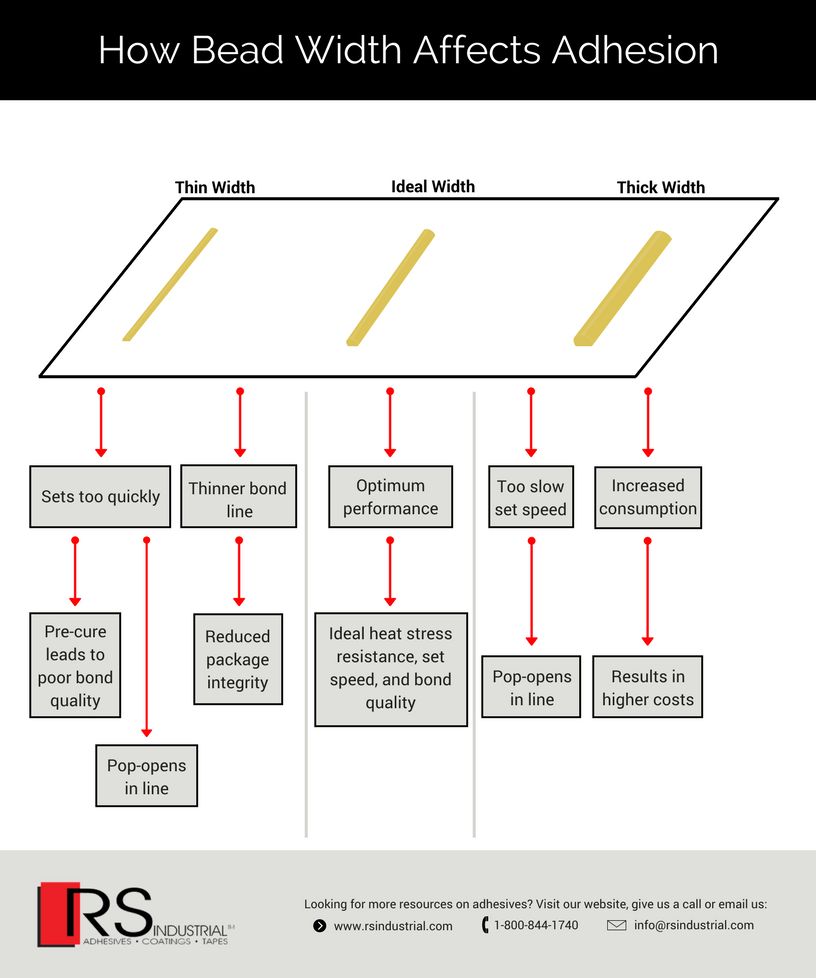

How much does the bead width of your adhesive matter? As it turns out, it matters quite a bit. Bead width is closely related to adhesive performance.

Perhaps you begin seeing pop-opens or poor adhesion on your packaging line. While there are many possible causes for these issues, your adhesive bead width could be one of them.

Applying a thick adhesive bead may cause your glue to set much slower, leading to pop-opens. Conversely, you don’t want to make the mistake of applying too little. A thinner bead could cause the glue to set too quickly and create poor bond quality.

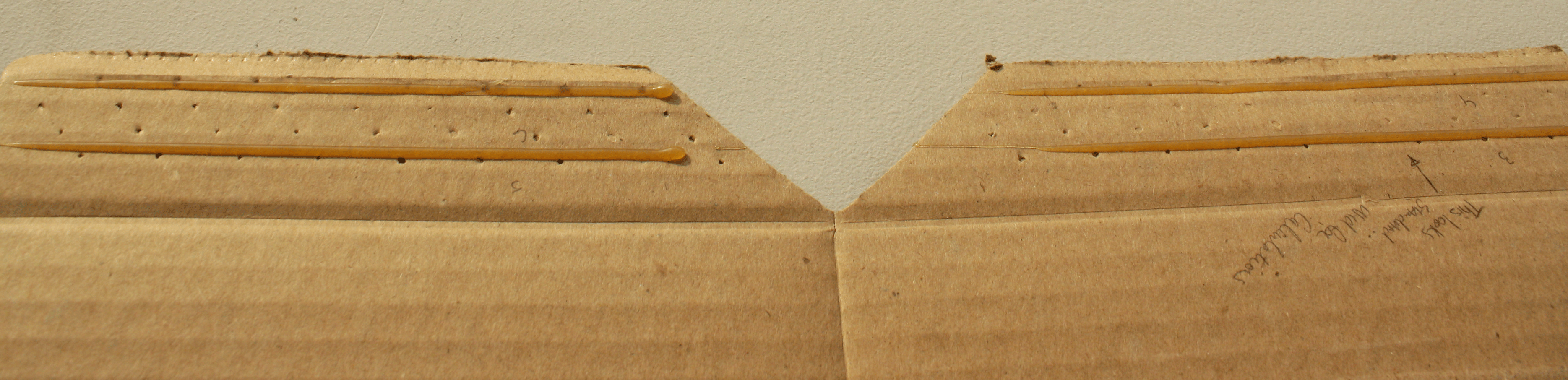

So what is the ideal bead width when applying adhesive? The answer isn’t the same for everyone. When working with our customers, we typically see an average thickness ranging from 0.10 to 0.12 inches. Keep in mind that this thickness does vary and will depend on your substrates and other application parameters.

Not sure how to measure your adhesive bead width? Watch our video on how to use a glue line measuring guide here.

We recommend working with an adhesive supplier that can visit your facility to look at your current process and evaluate your adhesive consumption. Applying just the right amount of adhesive can reduce adhesive failures and help save on costs.

If you’re interested in having one of our technical service analysts visit your location to review your process with you, use the contact form below or call us at 1-800-844-1740.