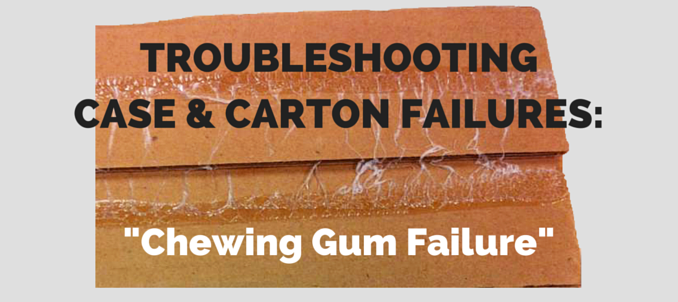

Troubleshooting Case & Carton Failures: “Chewing Gum Failure”

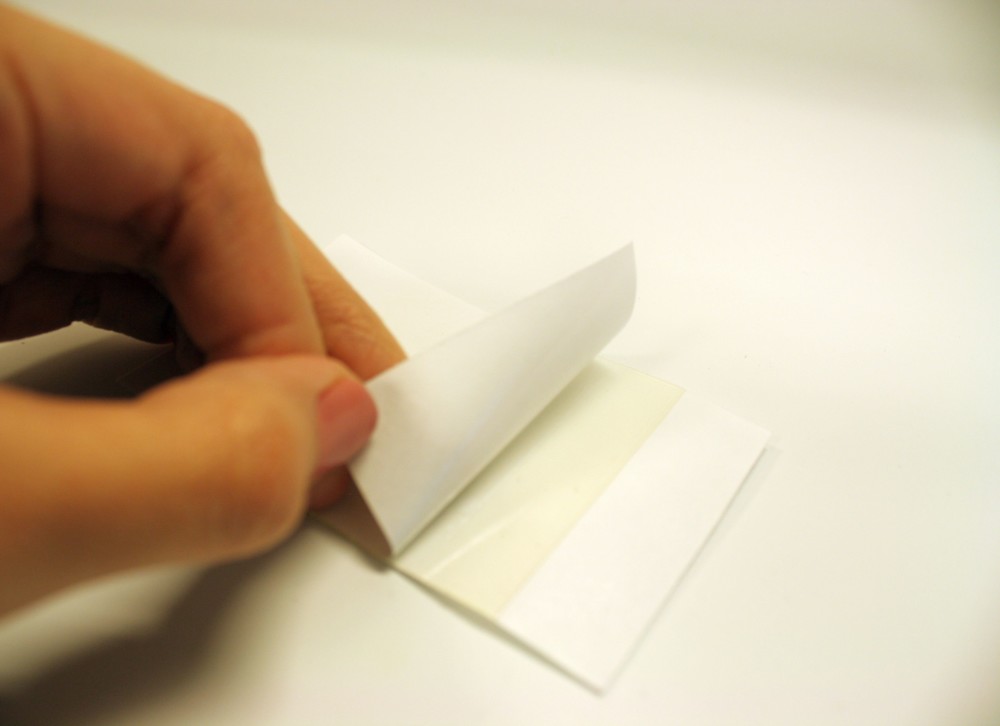

You’re wearing a brand new pair of shoes when you step on a wad of chewing gum. You can feel the gum stretching up from the ground as you lift your foot, revealing a stringy mess. Isn’t it the worst? In the world of packaging, industrial adhesives can behave in a similar way, which we