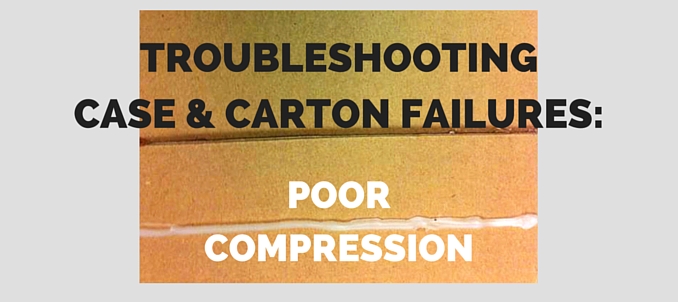

Troubleshooting Case & Carton Failures: Poor Compression

Identified the right type of adhesive? Check. Applied adhesive at the correct temperature and amount? Check. Successfully sealed your package? If you’re unable to check this off your list, there are a number of possible reasons why. One of the reasons your packaging may fail is due to poor compression. If you've missed our previous