Did you know that the craft of bookbinding was thought to originate in India? Religious scriptures were copied on to palm leaves with a metal stylus. The leaf was then dried and rubbed with ink, staining the wounds in the leaf. Twine was threaded through each end through wooden boards to create a palm-leaf book. Imagine how far we’ve come the next time you crack open a book!

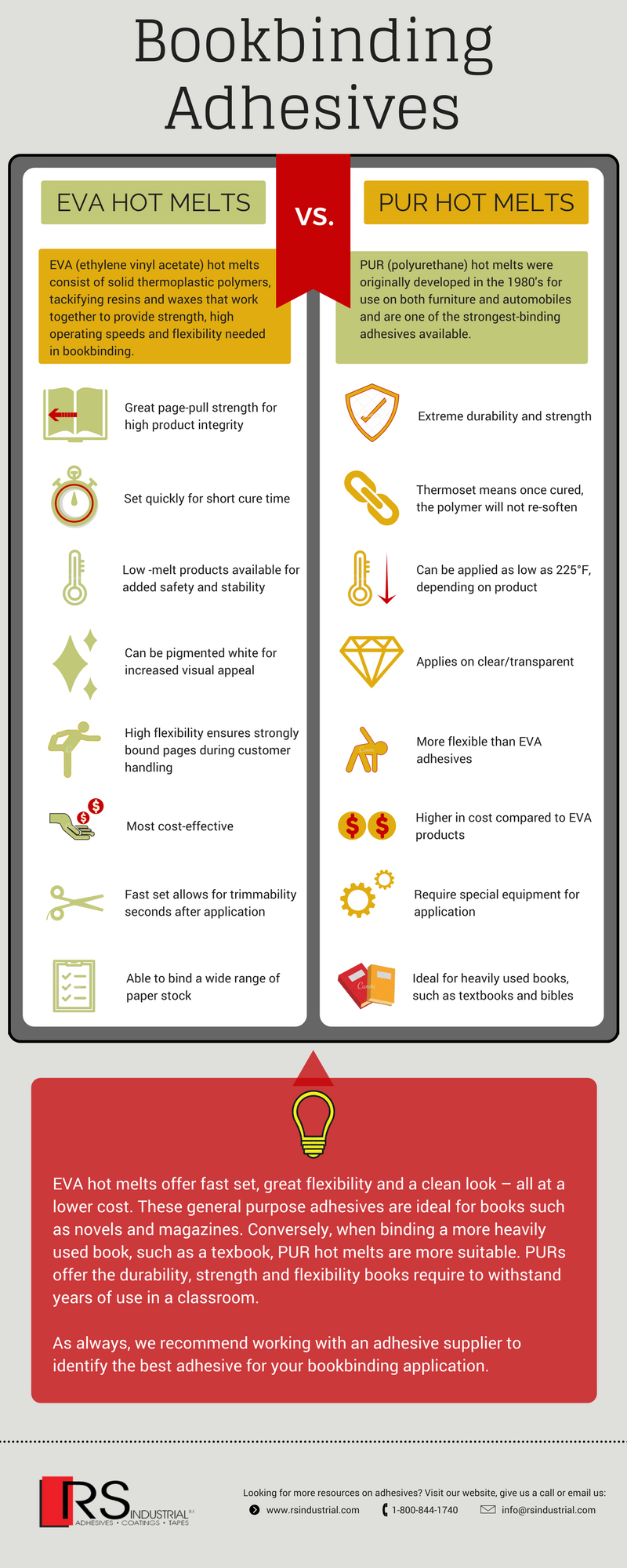

Fast forward to today, and the bookbinding process has evolved to rely on a range of adhesive solutions to ensure the books you enjoy reading stay intact. While there are many formulations available on the market, two primary adhesives are used in modern bookbinding today – EVA hot melts and PUR hot melts.

Bookbinding: EVA Hot Melts vs. PUR Hot Melts

Both EVAs and PURs come in hot melt form, but they differ in cost, strength, application and other characteristics. To see how these two adhesives compare, check out the infographic below.

Each adhesive has its pros and cons, so we recommend considering the demands of your bookbinding application. It’s likely that most EVAs will be suitable for binding novels and magazines. In contrast, PURs are a popular choice for textbooks or the most difficult-to-bond papers and book covers, due to their increased durability.

For more information or guidance on bookbinding adhesives, contact us at 1-800-844-1740 or use the contact form below. Our technical service team would be happy to discuss your application in more detail.