Case and carton sealing is one of our largest adhesive markets. There are many factors we consider when helping customers achieve a successful bond, but the substrate is one of the most important.

Before making any product recommendations, our technical service team will analyze your substrates. For instance, some substrates with coatings will require an adhesive that has a long open time to ensure penetration for a strong bond. Without the right adhesive, your case and cartons may face pop-opens or in-field failures, resulting in increased costs.

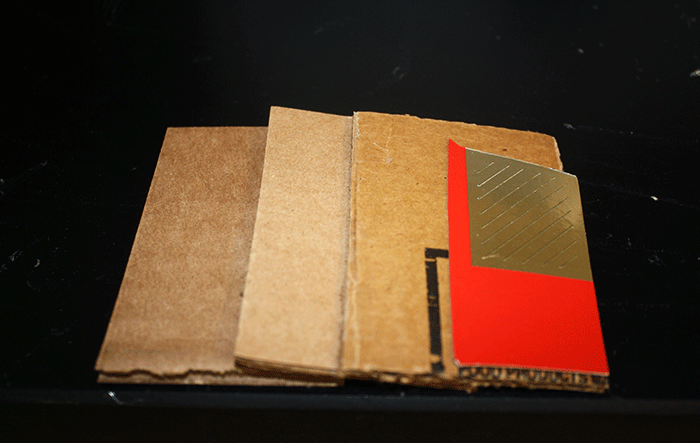

In our internal lab, we perform testing on the most common substrates to find the adhesive product that will produce the best results:

- Virgin corrugate– This is one of the easiest substrates to bond by use of standard EVA hot melts. Its fibers are interwoven and longer than recycled corrugate, allowing good wet out to occur on this substrate.

- Recycled corrugate– Vastly different than that of virgin, recycled corrugate is more difficult-to-bond. Its fibers are shorter and more compact, making it harder for adhesives to wet out on. Recycled corrugate is a popular substrate due to the rise of sustainability.

- Coated corrugate (clay, wax, poly)– Coatings such as these make it difficult for adhesives to penetrate the substrate. They require an adhesive with a long open time, allowing it to penetrate the coating acting as a barrier between the substrate and the adhesive.

- Metalized corrugate– This substrate requires a flexible adhesive with a high rubber content. This enables the adhesive to bond to the metalized PET rather than the corrugate itself.

At RS Industrial, we offer a full selection of adhesives ready to bond any of these substrates and more. Whether you’re dealing with a difficult-to-bond substrate, or aren’t sure which adhesive will provide optimal adhesion for your application, we’ll help you select the right adhesive. Contact us at 1-800-844-1740 or info@rsindustrial.com.