How Cyanoacrylate Glue May Increase Productivity

As a purchaser in manufacturing or assembly, you know that the supplies you select for the job will impact the quality of your final product. Although the adhesive can be a small part of the assembly process, it is the “glue” that literally and figuratively holds your product together.

Depending on your specific application requirements, cyanoacrylate glue is one of several solutions available for joining components in manufacturing and assembly.

What makes cyanoacrylate glue a good assembly option?

Here are five features of cyanoacrylate adhesives that make them an ideal solution for meeting common demands in manufacturing and assembly:

1. Provides Instant Cure

Cyanoacrylate adhesives aren’t called “instant adhesives” without proper reason. When your application requires an instant bond, you can rely on this type of adhesive to rapidly cure, increasing your production. Quick adhesion is one of the key advantages of a cyanoacrylate.

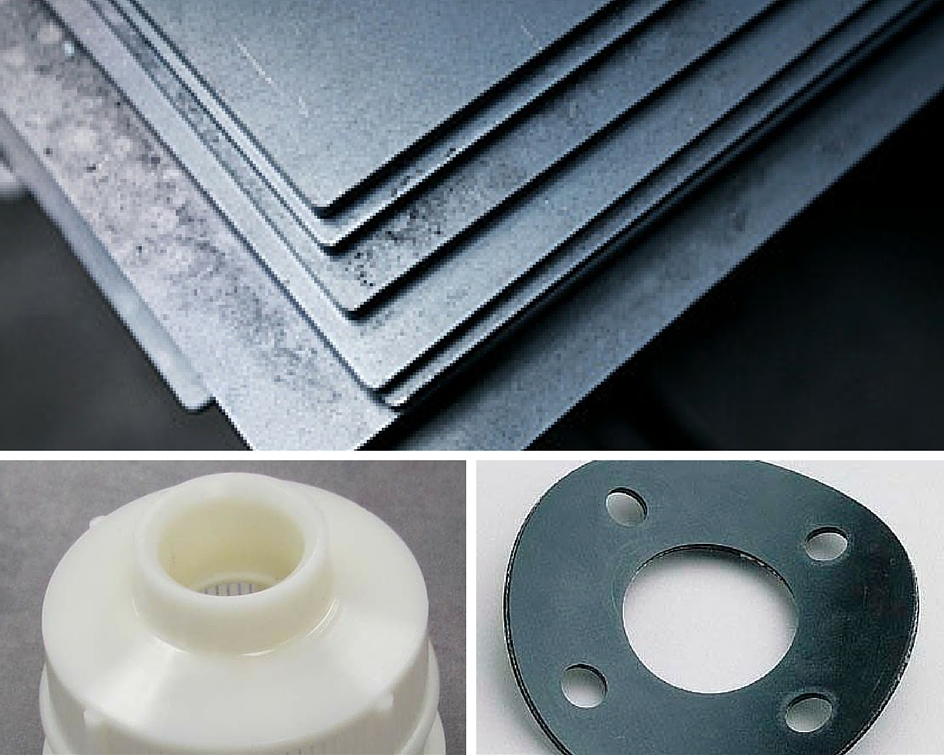

2. Bonds wide variety of dissimilar materials

Components that are common in manufacturing and assembly are undoubtedly made from some of the most difficult-to-bond materials. Combine that with the need to bond two completely different materials (rubber to metal, metal to plastic, etc.) together, and you’ve got what most would consider a challenging application. Cyanoacrylate adhesives can tackle these types of materials to create a durable, finished product.

3. Easy to apply

Cyanoacrylates are one-part adhesives. Unlike two-part adhesives, you can use instant adhesives straight from the bottle without the use of dispenser guns or static mixer nozzles for additional mixing. This simple, straight-forward application requires little to no staff training, allowing you to spend more time focusing on productivity.

4. Alternative to mechanical fasteners

Manufacturers are always looking for ways to create lower cost, lightweight, durable products. In some applications, cyanoacrylates can be used in place of mechanical fasteners such as rivets, nuts, and bolts to join together components. In many cases, instant adhesives can be a lower cost fastening method compared to mechanical fasteners, which require pre-assembly preparation and are labor intensive. Cyanoacrylates are also more aesthetically pleasing than mechanical fasteners, proving an “invisible solution.” (Our Adhesive Squares site has additional information on replacing mechanical fasteners with an adhesive.)

5. Resistance to chemicals and solvents

Cyanoacrylates perform exceptionally well in harsh environments where your product might be exposed to chemicals such as gasoline, motor oil, and toluene (non-polar solvents) during its end use. Although cyanoacrylates are able to resist these types of non-polar solvents, it’s important to remember that they have poor resistance to strong polar solvents like acetone and other corrosives.

Since cyanoacrylates are one of several adhesive assembly options, we recommend you work with a knowledgeable adhesive supplier to get the right product that best meets the requirements of your specific application.

To find out how our selection of instant adhesives can improve both your assembly process and final product, contact us at 1-800-844-1740 or info@rsindustrial.com. We’d love to learn more about your application!